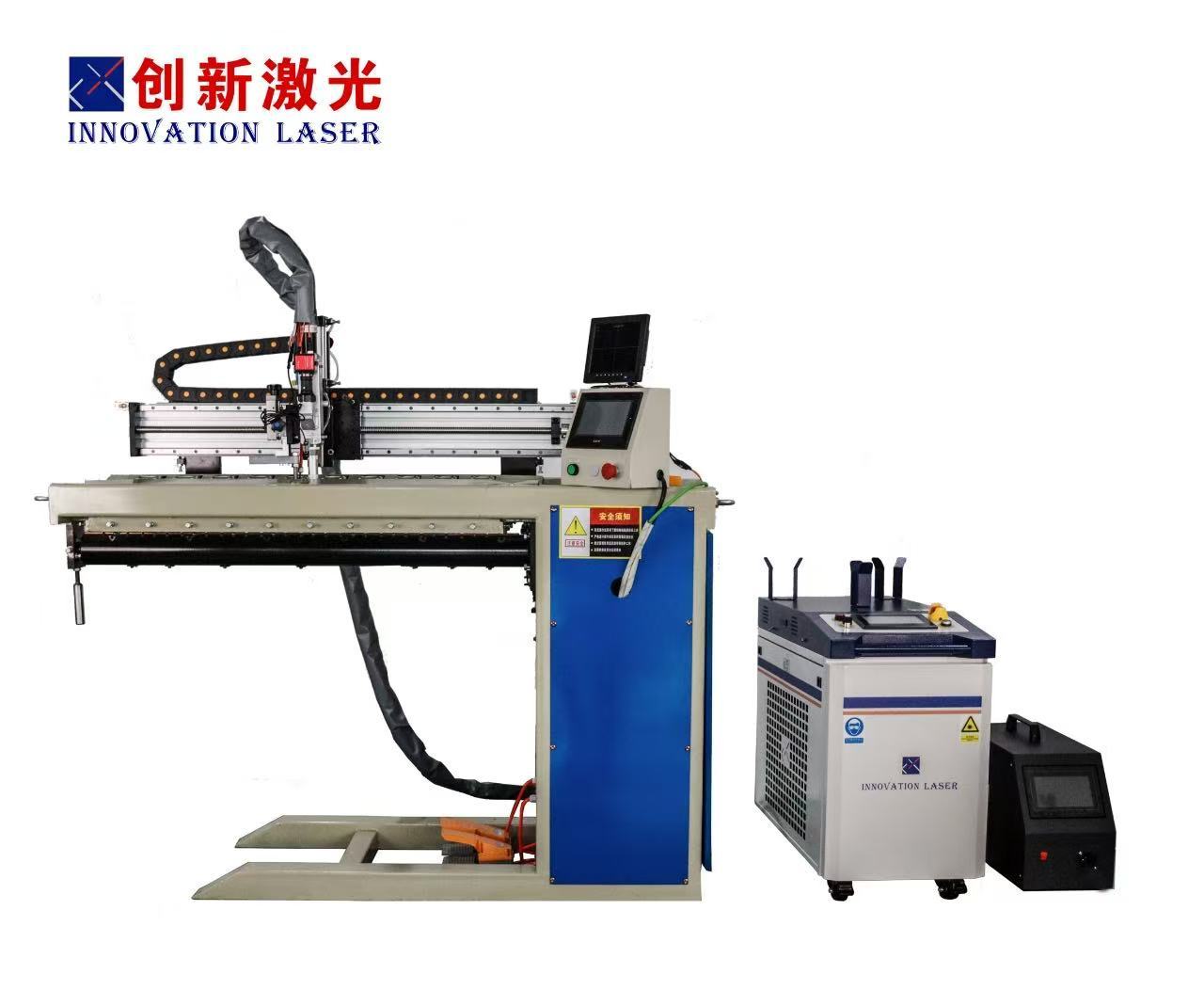

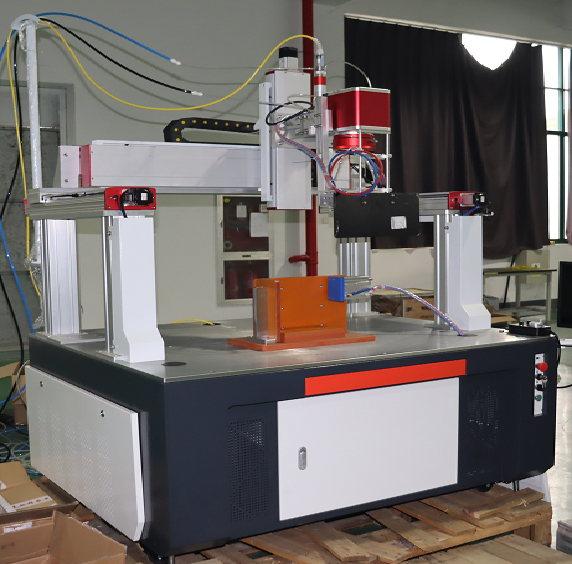

Galvo Scanning Welding Machine- Lithium Battery Welding Appilcation

Time:

2024-10-14

Author:

Wendy

Data source:

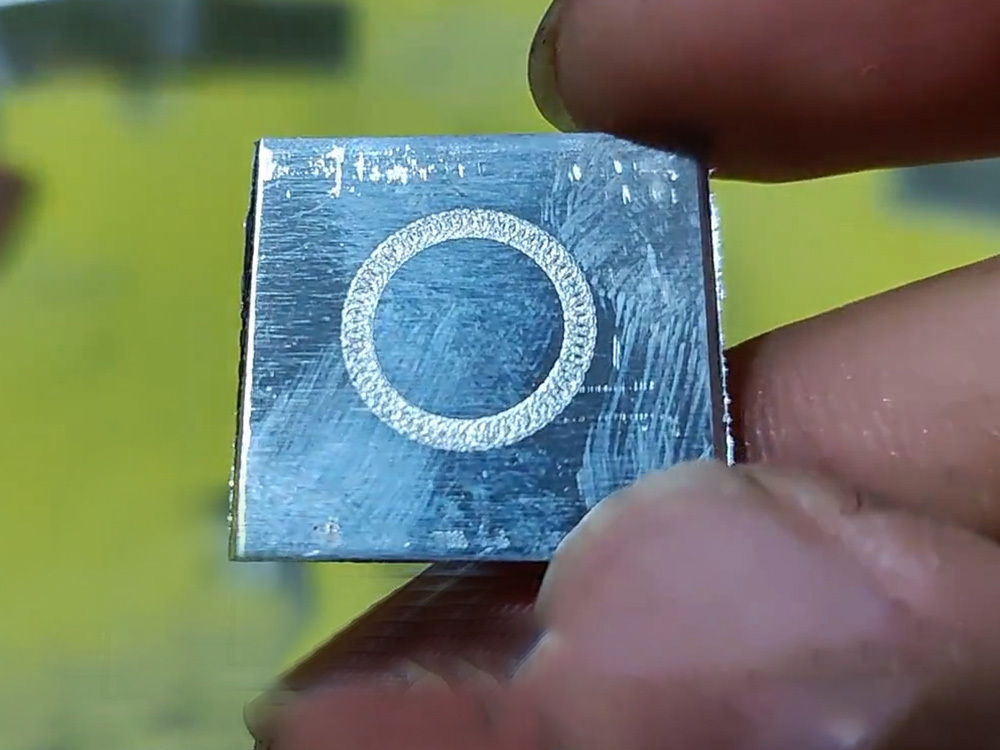

A battery module is composed of multiple batteries (square, cylindrical or blade-type) connected together through busbars (busbar). The production of safe and reliable battery modules has presented new requirements and challenges to electric vehicle manufacturers. Laser welding has become the mainstream technology in the battery manufacturing process, as it can ensure that the electrical performance requirements of the battery module are met, thereby ensuring the performance and reliability of electric vehicles. BUSBAR laser welding, which is typically performed using a ring-shaped laser beam, requires high welding speeds and quality, as well as a high level of welding process difficulty.

Advantages of Galvo Scanning Laser Welding for Battery:

1. Non-contact process: The materials used in manufacturing battery modules, whether busbars or individual cells, require very high yield rates. Laser welding does not touch the material, eliminating the risks associated with traditional connection methods.

2. High efficiency and reliability: Laser welding uses strict process control to ensure the high reliability of the Busbar welding process, greatly reducing downtime. Consistent processing can be achieved through control software and motion platforms to ensure the stability of laser power, thereby avoiding changes in the weld seam, which is a key factor in the quality control of Busbar.

Application of battery laser welding machine

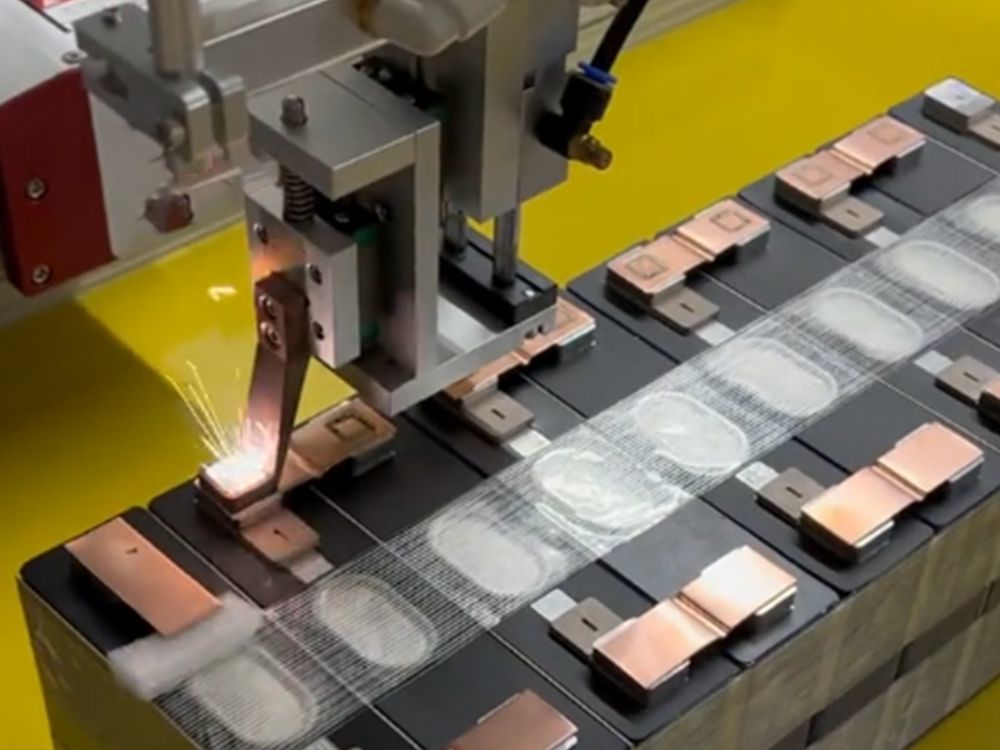

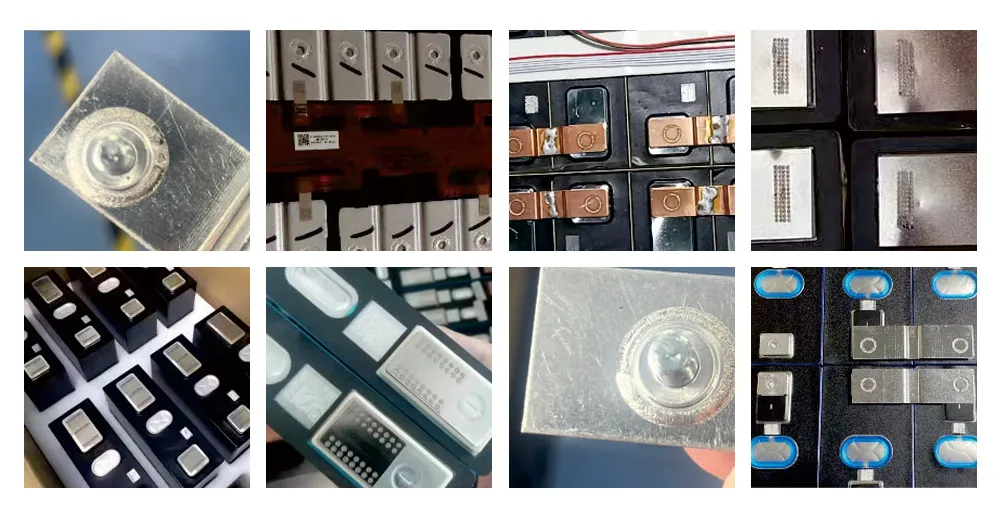

Battery pack welding: Large battery packs are the main source of power for electric and hybrid vehicles. Battery laser welders can be used to weld connections between cells or modules of battery packs. It ensures efficient current transmission and structural strength.

Battery cover welding: Battery packs are usually sealed with metal covers to ensure safety and prevent leakage of the components of the battery. The laser welding battery machine can weld the sealed connection between the battery cover and the housing.

Battery terminal welding: The battery pack must be connected to the vehicle's electrical system or other external power source. Battery laser welders can weld contacts between battery terminals and wires or connectors. This ensures reliable current transmission.

Battery radiator welding: High performance battery packs typically require heat sinks to control temperature and improve heat dissipation. The laser welding battery machine can weld the heat sink to the internal components of the battery pack for efficient heat transfer.

We are professional laser welding equipment provide, if you want to know more about how to improve the battery welding defect rate/output, email us: wangd@zjcxlaser.com or innovationlaser@zjcxlaser.com;

key word:

lithium battery welding,battery welding machine,galvo scan welding

RELATED NEWS

2024-11-12