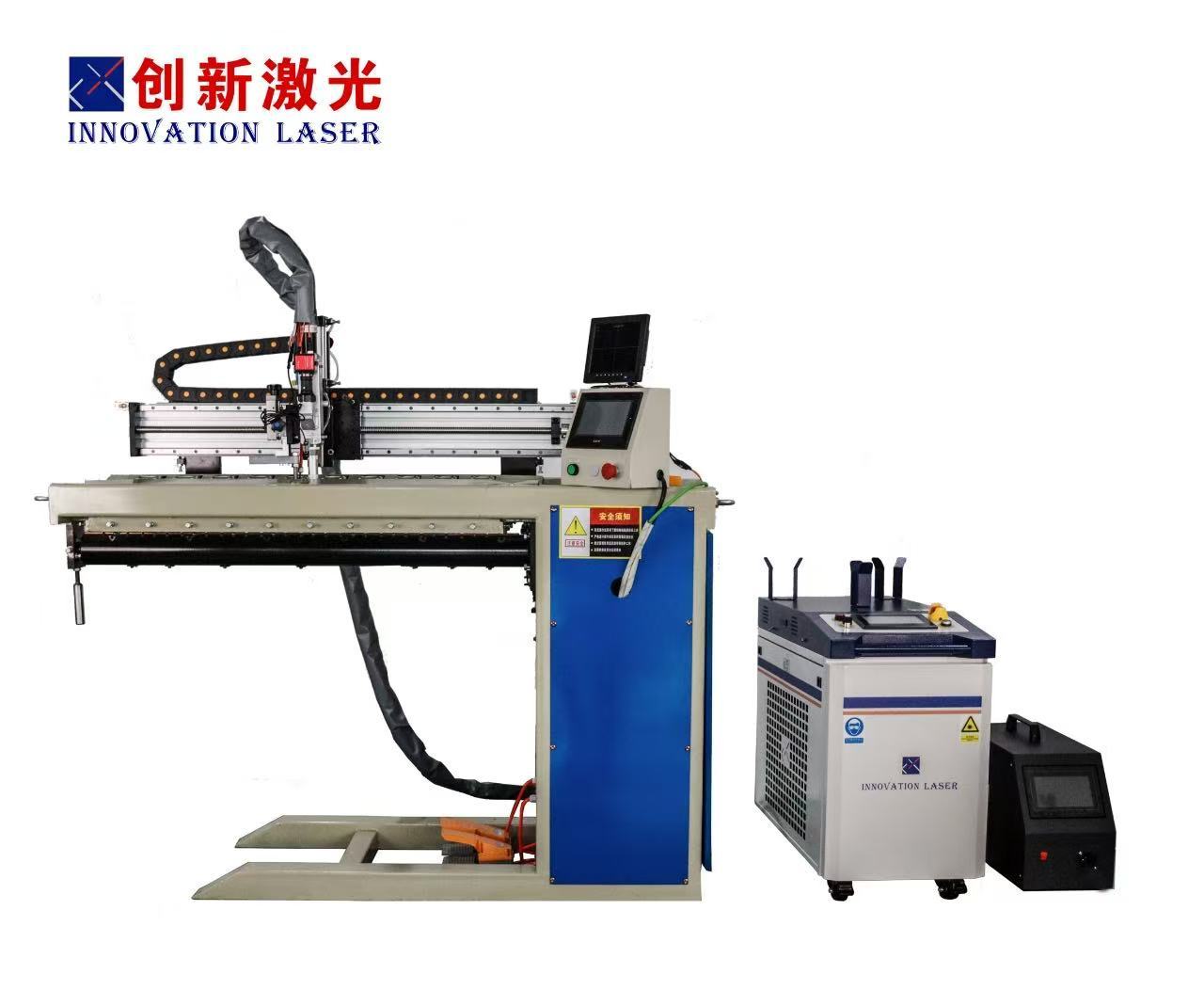

Customized Laser Welding Robot Station Dual Station with Safety Enclosure Yaskawa/ABB/FANUC Robot Optional

Time:

2025-02-20

Author:

Wendy

Data source:

Laser welding stations with dual-station designs offer significant advantages over single-station setups, as outlined below:

1. Significant Improvement in Production Efficiency:

Parallel Operations, Reduced Waiting Time: Dual-station setups enable simultaneous welding and loading/unloading, eliminating equipment idle time and maximizing robot utilization, significantly boosting production efficiency.

Shorter Production Cycles, Increased Output: The parallel operation mode effectively reduces the production cycle time per workpiece, allowing more workpieces to be welded within the same timeframe and increasing overall production capacity.

2. Higher Automation, Lower Labor Costs:

Reduced Human Intervention, Automated Production: Dual-station systems, combined with automated loading/unloading systems, enable unmanned operations, minimizing human intervention and lowering labor costs.

Reduced Labor Intensity for Operators: Automated production reduces the physical strain on operators and improves working conditions.

3. Greater Production Flexibility, Adaptable to Multi-Variety Production:

Quick Changeovers, Improved Equipment Utilization: Dual-station setups allow for pre-placed different fixtures, enabling rapid changeovers to meet the needs of multi-variety, small-batch production, thereby improving equipment utilization.

Adaptable to Flexible Production Needs: The dual-station design facilitates integration with other automated equipment, building flexible production lines to adapt to market changes.

4. Other Advantages:

Reduced Equipment Investment Costs: Compared to two single-station setups, dual-station equipment occupies less space and has lower investment costs.

Easier Maintenance and Management: Centralized control and management of dual-station equipment simplify maintenance and troubleshooting.

In summary, the dual-station design of laser welding stations offers significant advantages in improving production efficiency, reducing costs, and enhancing flexibility, making it an ideal choice for modern manufacturing to achieve efficient and automated production.

It is important to note that dual-station designs also require consideration of the following factors:

Equipment Cost: Dual-station equipment costs more than single-station setups.

Floor Space: Dual-station equipment occupies more space than single-station setups.

Programming Complexity: Programming and debugging for dual-station systems are relatively more complex.

In practical applications, it is necessary to comprehensively consider specific production needs, budgets, and other factors to select the most suitable configuration.

Contact us to learn more about the Fanuc Laser Welding Robot. We will provide you with professional solutions and services.

Zhejiang Innovative Equipment Co., Ltd. is a high-tech enterprise dedicated to providing advanced automation solutions for the manufacturing industry. We focus on the research, development, production, and sales of high-quality industrial robots, automated production lines, and related supporting equipment, helping enterprises achieve intelligent upgrades.

key word:

laser welding station,fanuc laser welding robot,welding robot,laser welding robot,laser welder,laser welding,welding robot dual station,laser weld

previous page

previous page