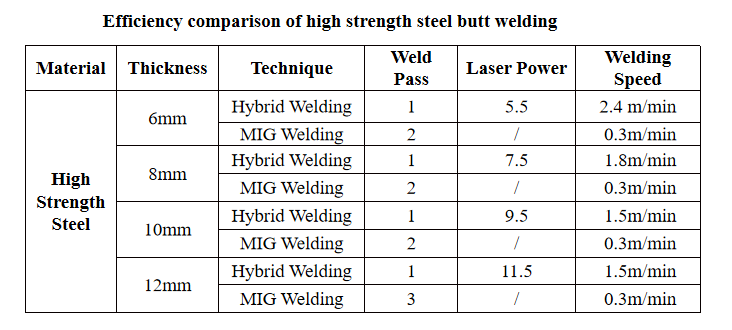

Hybrid Laser MIG Welding- A New Application Technology

Time:

2024-10-09

Author:

Wendy

Data source:

Hybrid welding is also known as hybrid laser-arc welding (HLAW).

This welding method was developed for simultaneously performing arc welding (such as MIG welding) and laser welding, thereby utilizing the advantage of both methods to make up for any shortcomings.

Hybrid welding is considered an effective means of achieving higher gap management tolerance, deeper penetration, lower heat input, reduced deformation and shrinkage, higher weld hardness and strength, higher fatigue resistance, improved welding speed and quality, and reduced costs.

Application in Hybrid Laser-MIG Welding

Its process characteristics can be applied to bridge, vessel building, containers manufacturering,automobile, rail transit, oil pipeline and other important fields;

Weld depth can achieve the thick plate (6-20mm) or large thick plate (more than 20mm) parts of the one-time single-side welding with double-sided molding;

No need to pre-welding process, it significantly improve efficiency, cost savings and it’s easier to achieve automation.

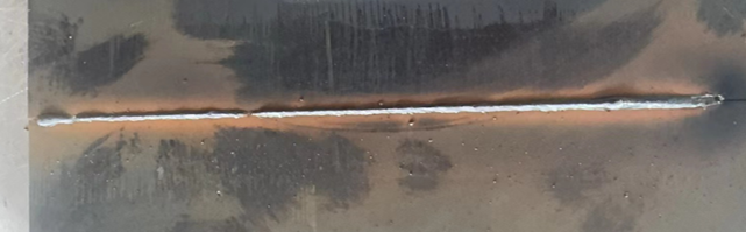

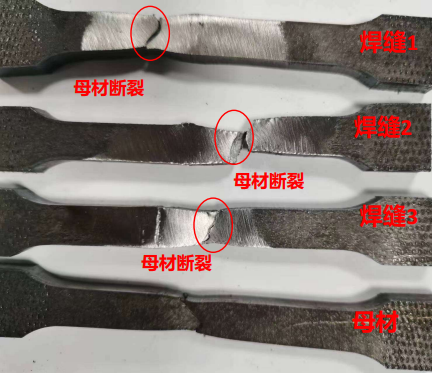

Picture of Welding Process Effect of Hybrid Laser MIG Welding

Fornt View

Back View

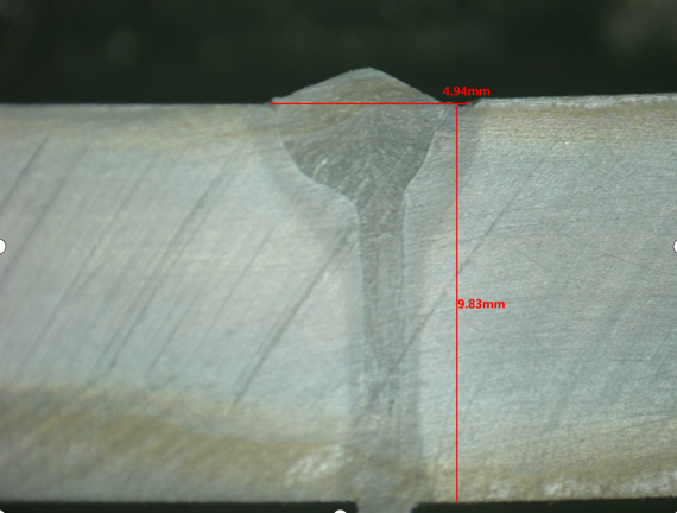

Welding Metallographic Analysis Diagram

| Tensile Strength MPa | |

| Base Material | 427 |

| Welds 1 | 406 |

| Welds 2 | 420 |

| Welds 3 | 405 |

Benefits of Hybrid Laser-Arc Welding

Hybrid laser-arc welding capitalizes on the advantages of two technologies. The first is the laser’s penetration ability and its fast speed. The arc allows the bridging of gaps, slow cooling of welds, and adjustment of metallurgical characteristics, due to the use of a filler wire. The laser’s deep penetration creates a very narrow heat-affected area. This allows welding at high speeds with lower heat input and distortion. These features of HLAW offer some key benefits. Hybrid welding greatly improves tolerances for joint fit-up. If real-time adaptive control is carried out, tolerances can be many times greater than with laser welding. Weld quality is improved as well. Hot cracking, the formation of shrinkage cracks during the weld metal’s solidification, can be avoided. Depending on the lasers and other parameters, single-pass penetration depth and welding speed can be increased.

Advantages of Hybrid Laser-Arc Welding in Industry

The advantages of the hybrid laser-arc welding process fit well with many industrial applications. Hybrid welding boosts speed and reliability on high-production automotive assembly lines. The greater tolerances ensure strong welds without as much time spent preparing the materials to be joined. The shipbuilding and rail transport industries benefit from the lower heat input and lower distortion of HLAW over other welding types, such as MAG (metal active gas) or SAW (submerged arc welding). The elimination of distortion correction and re-work dramatically reduce overall manufacturing costs. Reduced overall welding time also cuts further expenses.

key word:

Laser Welding,Hybrid Laser-Arc Welding ,Mig Welding,Welding Robot ,Thick sheet welding,Welding Technique,Welding Solution

Next page:

Next page: