Innovation Laser Welding Solution for GIS/RMU(Electricity Application)

Time:

2024-10-30

Author:

Wendy

Data source:

1.Introduction

In an electrical power distribution system, a ring main unit (RMU) is a factory assembled, metal enclosed set of switchgear ,filled with isolated gas ,used at the load connection points of a ring-type distribution network.

Why is laser welding suitable for electricity products like RMU, GIS and Electrical Cabinet/Panel Boards?

1.High Effiecncy, High Precision , Stability;

2.No Grinding/Post Weld Process;

3.Easy to be Automated,Labor Cost Saving;

4.Enviroment Freindly;

Laser Welding Is the Trend for Mass Production Welding.

We offer a turnkey solution for our customers which engage in producing electrical box/panel/board, especially for those who manufactur GIS/RMU cabinet;

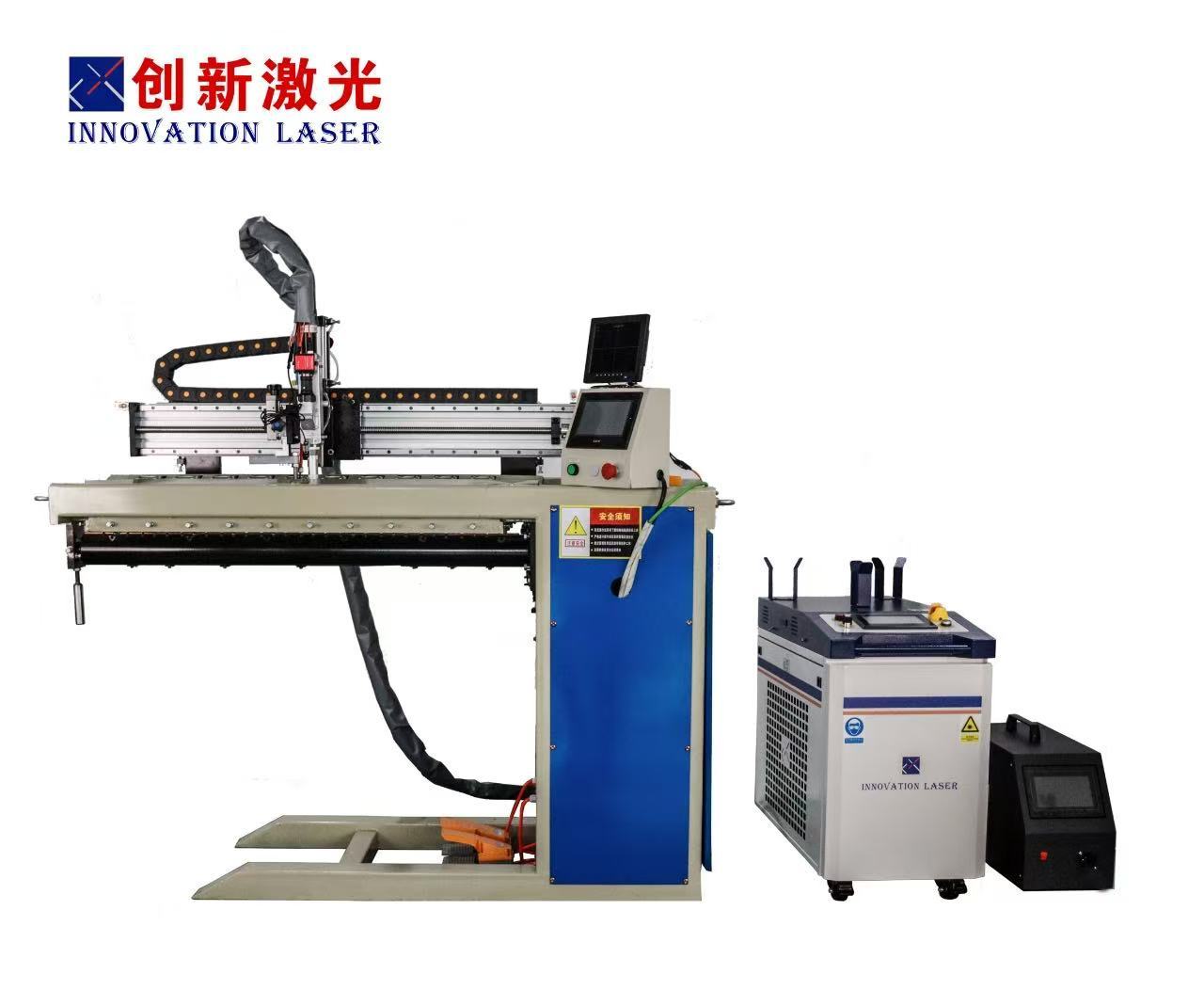

2. Solutions from Innovation Laser

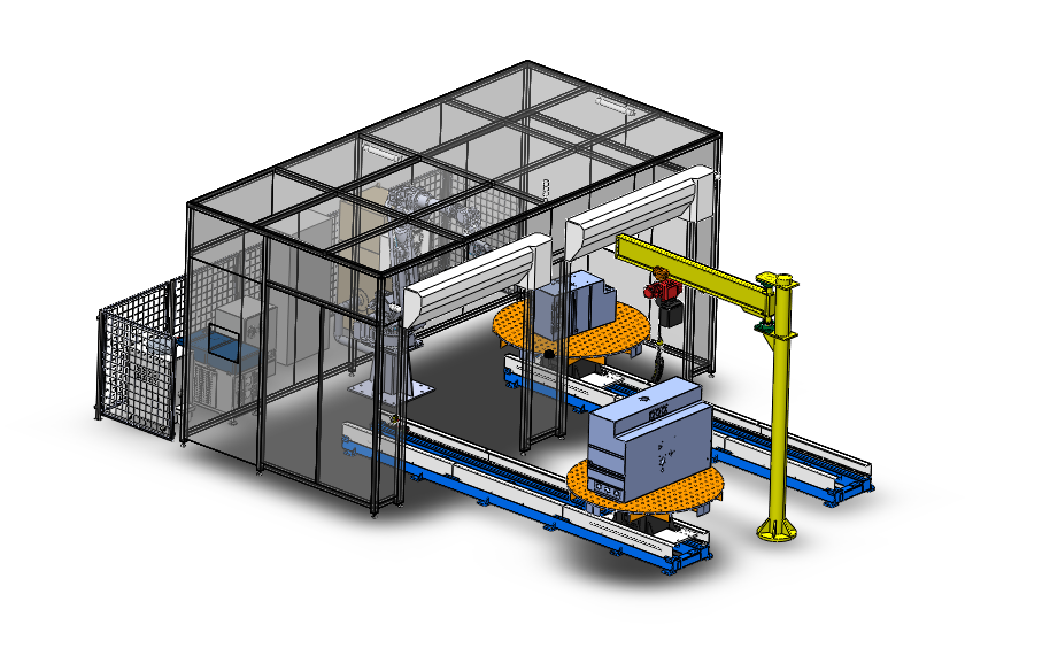

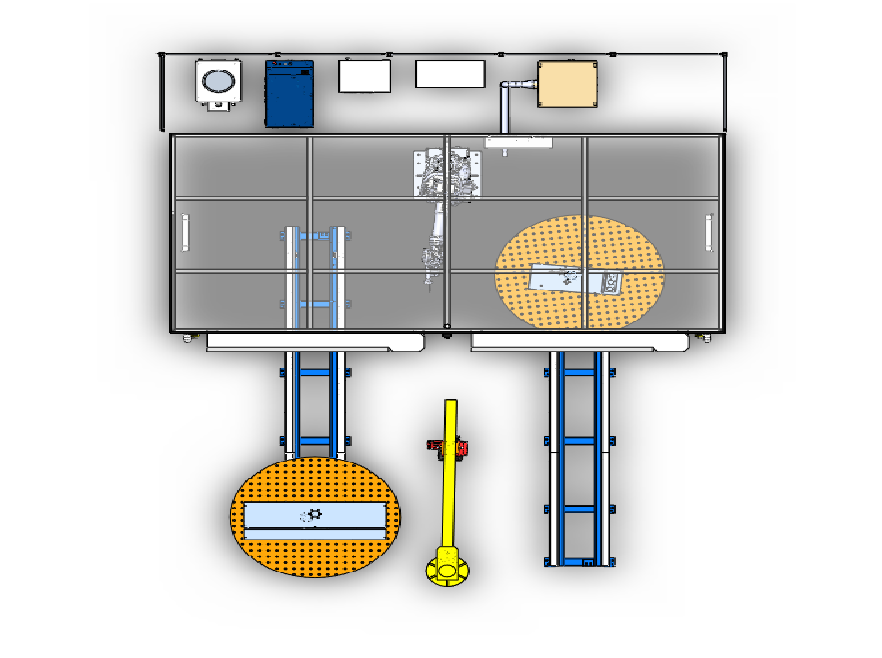

Typical Solution One: Robotic Laser Welding Cell with 2 Workstation( in and out );

Features:

3. 1. Independent welding room with dust collector offers friendly enviroment;(we offer the design draft for cutomers);

3. 2 Laser welding robot is intergrated with seam finding function.

3. 3 Two postioners improve the effiency and guarantee robot to work continuously.

3. 4 Continous welding process at corners assures the gas sealing quality;

3. 5 Capacity:≧8min/set(It depends on the product size);

3. 6 product percent of pass:≧98%

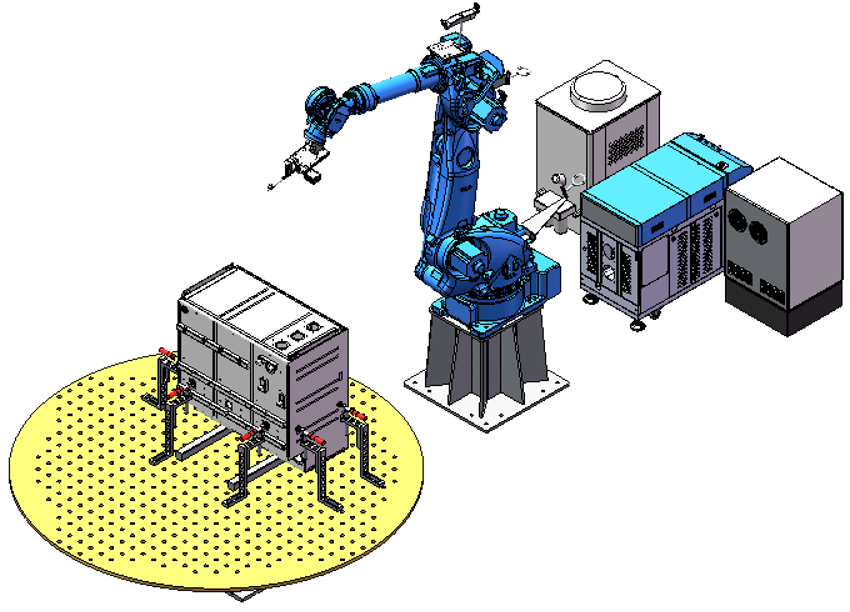

- Typical Solution Two: Robotic Laser Welding System with 1 Workstation( Rotary Postioner );

Please Click here to see the vidoe:

Please Click here to see the vidoe:

3. Customer Site View

Our system features advantages as below:

1.High-precision laser sensor: This sensor is able to scan the welding area in real time and generate a three-dimensional image of the weld. By analyzing the image data, the control system is able to accurately identify the weld position and shape, thereby guiding the welding gun to make dynamic adjustments.

2. Improve production efficiency: The system realizes the automation and intelligence of the welding process, greatly reducing manual operation and improving production efficiency.

3. Strong adaptability: The system is suitable for a variety of complex weld shapes and positions, and can meet the welding needs of different electric cabinet frames.

4. Easy operation: humanized operation interface, no need for professional welding robot operation experience, reduce the difficulty of operation.

5. Safe and reliable: The system has the ability to resist interference such as arc light, smoke, splash, etc., to ensure stable work in harsh environments.

Contact us for more details and get free solutions : wangd@zjcxlaser.com&innovationlaser@zjcxlaser.com;

key word:

robotic laser welding ,RMU welding,GIS welding,laser welding electrical box