The Advantages of the Production Automation Scheme Combining Yaskawa Robots and Laser Welding Systems

Time:

2024-10-31

Author:

Data source:

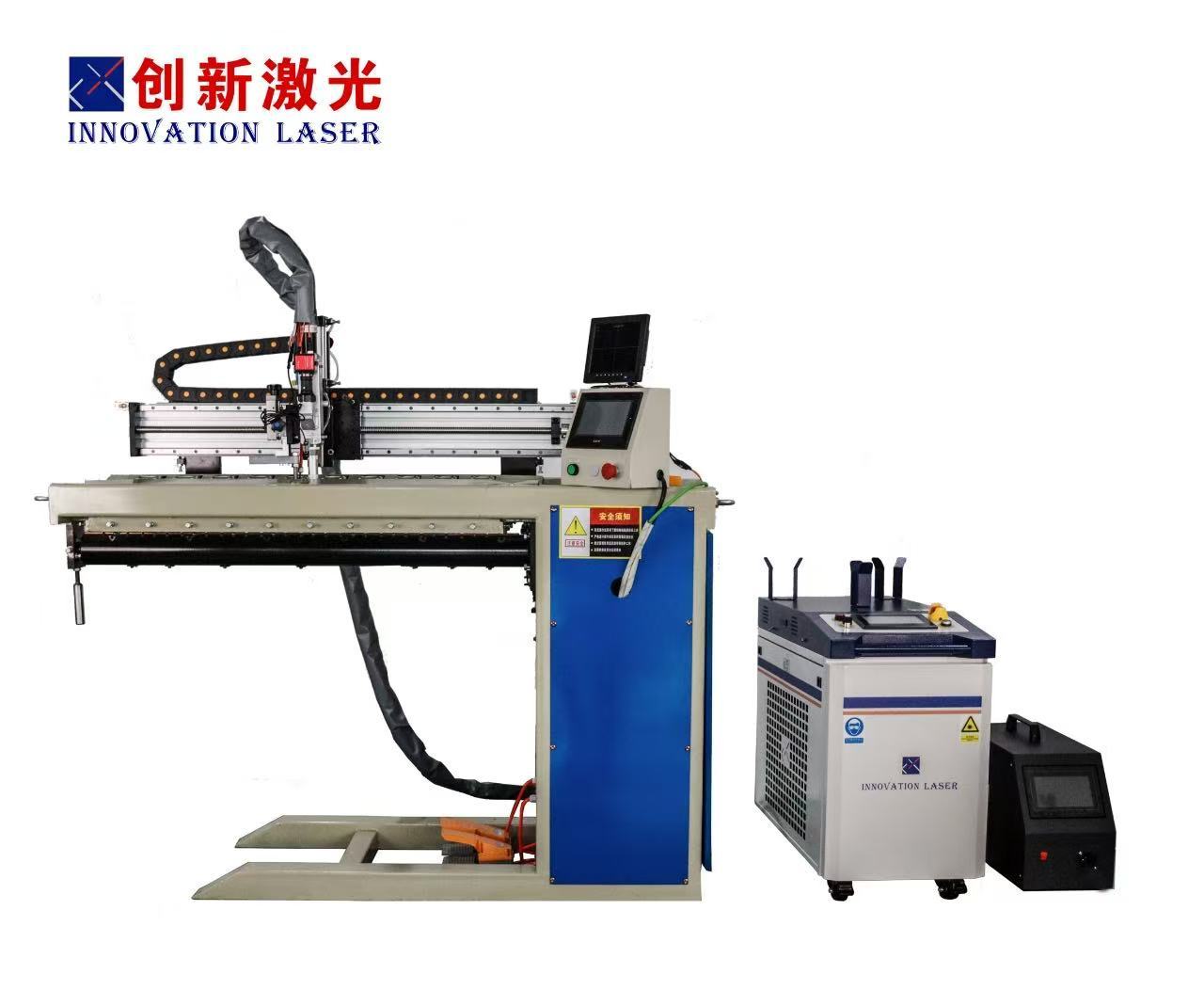

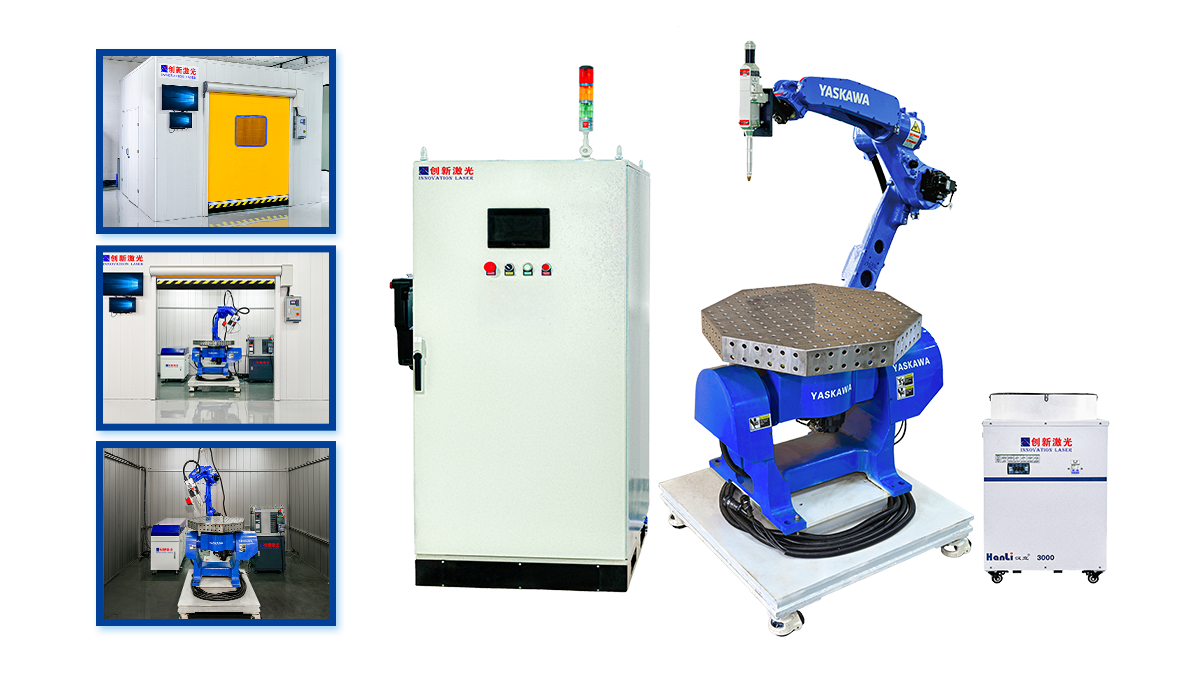

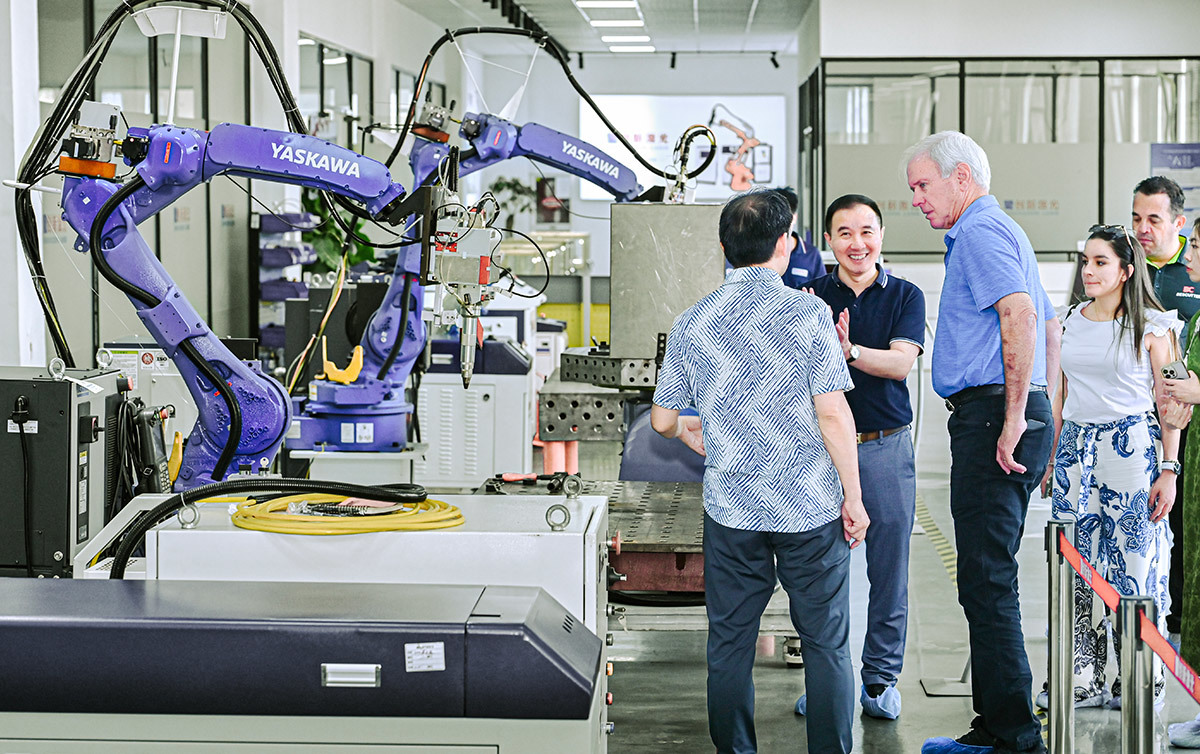

In modern manufacturing, the combination of Yaskawa robots and laser welding systems has emerged as a highly effective production automation solution, bringing numerous remarkable advantages.

High Precision and Quality

Yaskawa robots are renowned for their exceptional accuracy and repeatability. When paired with laser welding systems, which offer extremely precise energy delivery and narrow heat-affected zones, the result is welding work of outstanding precision. The robot can precisely control the movement and positioning of the welding head, ensuring that the laser beam is accurately focused on the joint to be welded every time. This combination minimizes welding defects such as porosity, cracks, and incomplete fusion, leading to high-quality welds that meet the strictest industry standards. The consistent precision also enables the production of uniform and reliable products, which is crucial in industries like automotive and aerospace where component integrity is of utmost importance.

Increased Productivity

The automation achieved by using Yaskawa robots and laser welding systems significantly boosts productivity. Robots can work continuously without the need for breaks, fatigue, or shift changes like human operators. They can execute welding tasks at a much faster pace, following pre-programmed paths and sequences with high efficiency. The laser welding process itself is also relatively quick compared to some traditional welding methods, as it delivers concentrated energy to quickly melt and fuse the materials. Together, this combination allows for a much higher throughput of welded components, reducing production cycle times and enabling manufacturers to meet tight delivery schedules and increasing overall production output.

Flexibility and Adaptability

Yaskawa robots are highly programmable and can be easily reconfigured to handle different welding tasks and product geometries. Whether it's welding complex curved parts or simple straight joints, the robot can be adjusted accordingly. The laser welding system can also be tuned to different power levels and welding parameters to suit various materials and thicknesses. This flexibility makes the combined automation scheme suitable for a wide range of manufacturing applications. Manufacturers can quickly switch between different product lines or make modifications to existing products without significant retooling or downtime, providing great adaptability in a constantly changing market environment.

Enhanced Workplace Safety

Welding operations often involve hazards such as intense heat, bright light, and harmful fumes. By replacing human operators with Yaskawa robots in the welding process, the risk of workers being exposed to these dangers is greatly reduced. The robots can perform the welding tasks in enclosed or shielded areas, while operators can monitor and control the process from a safe distance. This not only protects the health and safety of the workforce but also reduces the likelihood of workplace accidents and associated costs such as medical expenses and lost productivity due to injuries.

Cost Savings

In the long run, the combination of Yaskawa robots and laser welding systems can lead to significant cost savings. The increased productivity means more products can be manufactured in a given time, spreading fixed costs over a larger output and reducing the unit cost of each product. The high quality of the welds reduces the need for rework and scrap, saving on material and labor costs associated with fixing defective welds. Additionally, the reduced labor requirements due to automation mean lower labor expenses, although some skilled technicians are still needed for programming, maintenance, and supervision. Overall, these cost-saving factors contribute to improving the profitability of manufacturing operations.

In conclusion, the production automation scheme that combines Yaskawa robots and laser welding systems offers a host of advantages, including high precision and quality, increased productivity, flexibility and adaptability, enhanced workplace safety, and cost savings. It is a powerful solution that is driving innovation and efficiency in modern manufacturing industries.

key word:

robotic laser welding,automatic welding,yaskawa welding

previous page

previous page

RELATED NEWS

2024-11-12